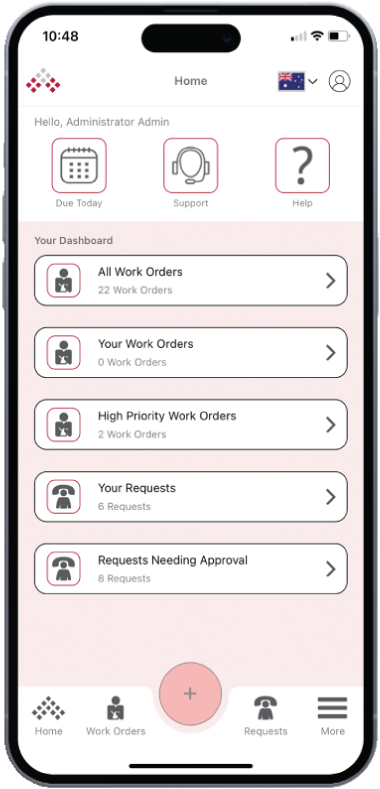

FleetMEX is a comprehensive Computerised Maintenance Management System (CMMS) specifically designed to help streamline the maintenance of your vehicles and equipment. From pre-start checks to scheduling preventive maintenance, generating work orders, and managing requests, FleetMEX ensures that you always have the data and tools you need to keep your fleet running at peak performance.

With an intuitive interface and powerful features, FleetMEX reduces downtime, optimises resource allocation, and provides full visibility into the health of every vehicle under your watch.

By prioritizing equipment maintenance, you can achieve direct and measurable savings, contributing to the overall financial success of your business.

MEX helps organizations manage their assets throughout their entire lifecycle, from acquisition to disposal.

MEX’s versatility makes it suitable for a wide range of industries and applications. Implementation can be as basic or complex as the user intends it to be.

With MEX's scheduled maintenance and inspections, your equipment operates efficiently and experiences fewer breakdowns.

With comprehensive data captured for each asset, you can quickly generate reports to analyze equipment performance, costs and ensure compliance with auditing requirements.

MEX can help organizations comply with regulatory requirements by ensuring that all maintenance activities are recorded & reported accurately.

At MEX, we pride ourselves on fostering a customer-centric culture that places a strong emphasis on providing top-notch customer service, comprehensive support, and effective training.

David W

Firstly, MEX is user friendly, very easy to navigate through all the modules. Mex catalogue for spares is extremely important to us and is easy to set up and maintain. Currently introducing barcoding to our catalogue. Customer support is clear & very helpful when required.

Philip G

MEX is already showing the business that we are top heavy with trades waiting around for break downs, with this information we now can plan more effectively by having trades onsite when required to carry out planned maintenance activities and not just be a breakdown team giving them more machine up-time