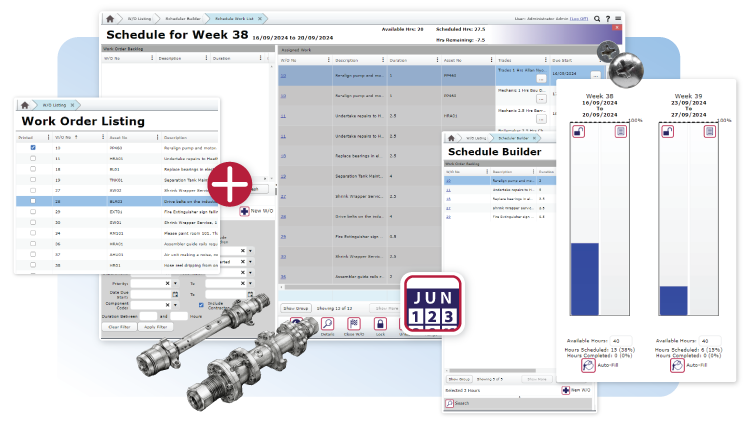

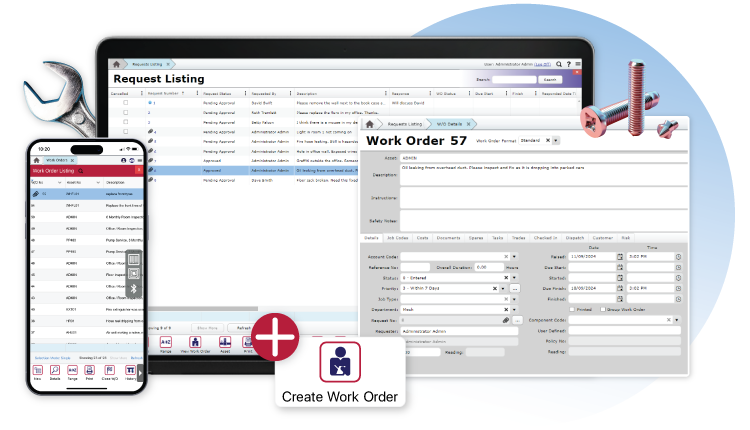

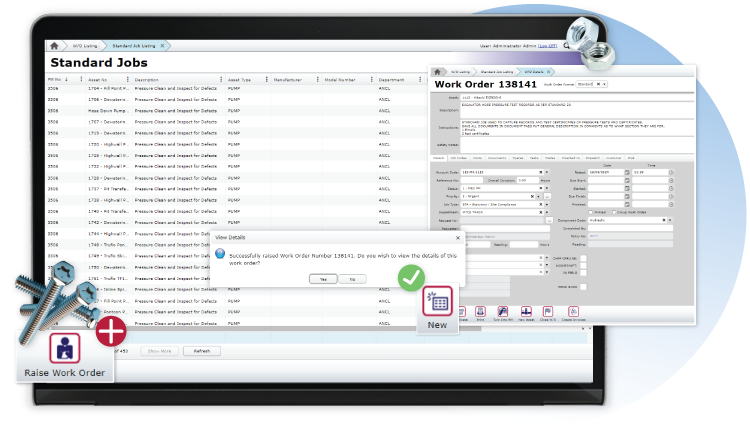

Streamline Your Maintenance with MEX Work Orders

Simplify your maintenance management with MEX Work Orders. Capture all the necessary details, assign tasks, and track progress in real-time. Our intuitive interface allows you to manage work orders from creation to completion, ensuring nothing slips through the cracks and reducing equipment downtime.